31 Home Improvements That Will ...

- 4

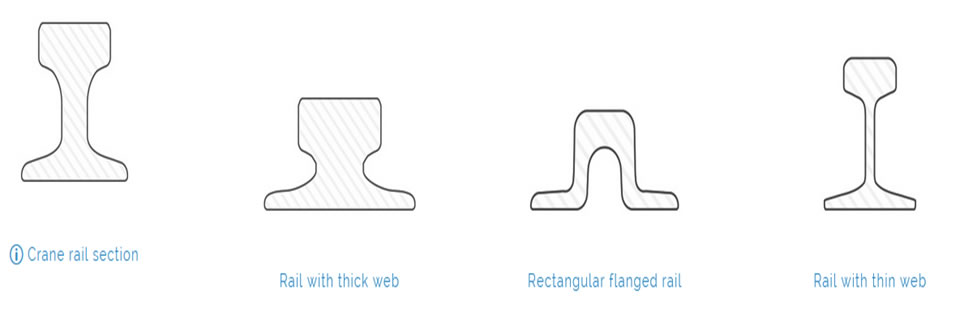

We provide a complete crane rail system solution, including rails and fasteners. We have a wide range of international crane rail and rail profiles available for your project, with over 100 rail selections to choose from. The main types include crane rails with thick webs, railway rail style with relatively thin webs, and sections which are rectangular but have flanges to form a foot. The crane supplier may suggest a rail, but if not, they should at least supply the head width of the rail.

The main types of rail selections are as follow:

Our experts can help you select the right rail and capacity for your needs, depending on local availability and steel strength.

We offer a range of rail clips designed to attach the rail to the track supporting structure. Clips are made of metal and are designed to securely hold the rail laterally while also allowing for some longitudinal movement and expansion due to temperature change and other factors.

We offer a range of rail clips designed to attach the rail to the track supporting structure. Clips are made of metal and are designed to securely hold the rail laterally while also allowing for some longitudinal movement and expansion due to temperature change and other factors.

Our clips are suited for every application that requires fixing a rail track, such as industrial overhead cranes, transfer cars, STS and automated portal cranes, stacker-reclaimers, loaders and unloaders for bulk material handling, automated stacker cranes for warehouse industry, special heavy load applications such as retractable roofs and rocket movers. Our clips also feature lateral adjustment to facilitate installation and allow for further corrections to the track geometry throughout its life.

Designed as stress resistant, the mechanical performances have been certified and tested by worldwide renowned laboratories for the specialized Rail Tracks Construction.

Designed as stress resistant, the mechanical performances have been certified and tested by worldwide renowned laboratories for the specialized Rail Tracks Construction.

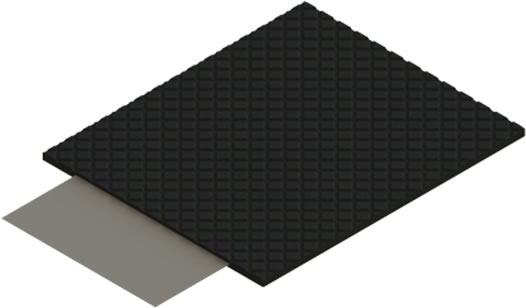

We offer a range of rubber pads, designed to be placed between the rail foot and the track supporting structure. These pads are typically made of rubber and are designed to reduce wear and tear on the rail and other track equipment by distributing the load more evenly across the supporting structure, and by absorbing impacts and vibrations caused by the passage of cranes.

Our pad range covers all rail profiles and includes continuous and discontinuous pads.

The rubber pads are designed to provide load distribution over a larger surface, eliminate load concentrations and ensuing fatigue stresses, center loads on the supporting element, absorb uneven contact surfaces between rail and support, and reduce wear of the rail and its support.

We offer a range of steel supports for runway tracks, including soleplates and chairplates (baseplates/support plates), steel sleepers, and steel columns. These steel supports provide the rails with a flat, smooth resting surface which allows for the vertical alignment of a rail system.

We offer a range of steel supports for runway tracks, including soleplates and chairplates (baseplates/support plates), steel sleepers, and steel columns. These steel supports provide the rails with a flat, smooth resting surface which allows for the vertical alignment of a rail system.

Whilst anchor bolts secure the steel supports, specific levelling devices adjust the vertical level. Depending on the specific industry application and moving equipment (cranes or rolling stock), steel supports are installed on top of a layer of grout or concrete that fills the void between the steel support and the concrete foundation.

Continuous Soleplates

Continuous Soleplates

For heavy duty applications with wheel loads of >30 tonnes, continuous rail support on steel soleplates is the recommended option. Soleplates are typically 6 meters in length and tend to be supplied with a thickness of 20mm or more. The soleplates are often galvanised for outdoor applications, and welding must be done before galvanising for rail clips.

Discontinuous / Individual Soleplates

We have many years of experience in installing individual sole plates in a variety of industrial and storage applications. We can supply suitable designs, materials, and installation when required.

Installation of a crane rail system is essential to the success of any project. Our experts provide the highest levels of planning, analysis, and safety to ensure your system is installed correctly and efficiently.

Fenders System

We have strategic partnerships with PIANC registered manufacturers with over 20 years of experience delivering marine fender system solutions to Asia, North America, Central & South America, Europe, and the Middle East. Our global network provides an end-to-end solution that is customized to project requirements, providing detailed support in close proximity to our valuable clients.

Types of fenders

Marine Rubber Fenders are critical for the energy absorption of a berthing vessel into the berth structure. Our fenders are designed to protect the berthing structure without damaging the vessel hull for all potential vessel types, sizes, and approach scenarios. We offer a full range of fender options to compliment our marine steel picking products.

Marine Rubber Fenders are critical for the energy absorption of a berthing vessel into the berth structure. Our fenders are designed to protect the berthing structure without damaging the vessel hull for all potential vessel types, sizes, and approach scenarios. We offer a full range of fender options to compliment our marine steel picking products.

Cathodic Protection of wharf structures is an effective method of corrosion protection. We have the capability to design, supply, install, and commission cathodic protection systems, which typically utilise an anode made of aluminium or zinc alloy bolted or welded to the steel structure. This forms a galvanic cell where the anode oxidizes preferentially to the steel, hence reducing or eliminating the rusting of the steel.

Graha Sentana, Jl. Warung Buncit Raya No.2, RT.3/RW.2, Duren Tiga, Kec. Pancoran, Jakarta Selatan, 12510, INDONESIA

© 2023 PT Danakaya Dian Samudra. All Rights Reserved. Designed By RUBI